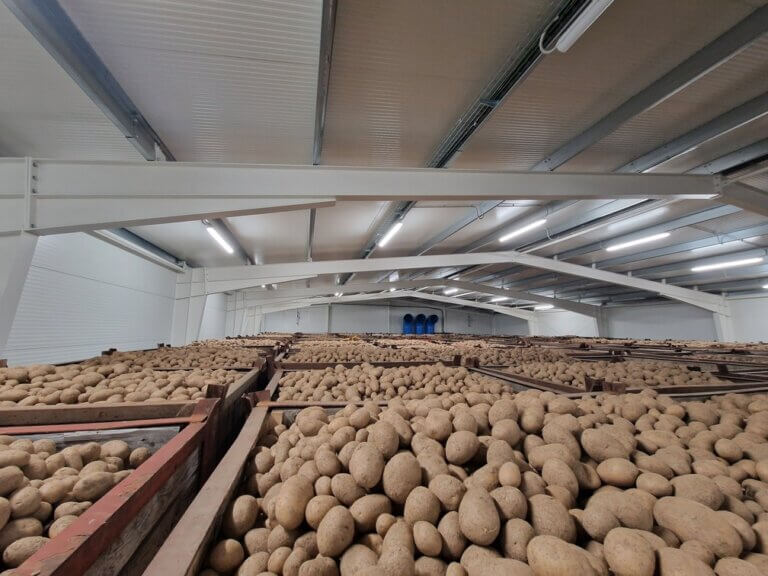

Pallet Storage Systems

Pallet storage units are suitable for storing potatoes, fruit and vegetables. Pallet storage is preferable to many products, because the pressure on the bottom of the pallet is much smaller than that of bulk storage. Pallets also provide great flexibility and allow for the storage of different varieties in one storage room. Agroel recommends its Integrated Mixing Chambers (ISK) – an affordable climate control system for these types of warehouses.

AGROEL ISK INTEGRATED MIXING CHAMBERS

An integrated mixing chamber can work in a variety of modes: an ambient ventilation mode using outdoor air for cooling, a refrigeration mode or a combination of the two modes. Significantly lower operation costs of ambient ventilation are arguments for combined ventilation and refrigaration systems, compared with storage facilities equipped only with a refrigeration system. Cool air (either ambient, mixed or refrigerated) is blown by the ISK above the top pallets, and then it drops by it’s own weight in spaces between pallets. The so-called „top ventilation“ limits water condensation in the top pallets and therefore significantly reduces the risk of storage diseases. ISK units supply large amounts of air in high velocity, sufficient for evenly covering the whole storage volume.

Depending on installed equipment, the ISKs can work in several modes:

- Ventilation using ambient outdoor, indoor and mixed air.

- Primarily ventilation (as described in point 1) and refrigeration – when outdoor-air temperatures are unsuitable for ventilation..

- Only refrigeration – for special cases.

- Ventilation, refrigeration and humidification. Humidification panels can be used not only to humidify the supplied air, but also to utilize a significant cooling effect when dry air passes through them.

Advantages of ISK pallet-storage solutions:

- All in one block – fans, insulated control hatch, air-supply pipes, evaporator, humidifier

- Easily adaptable to any kind of building

- Simple and fast on-site installations

- Affordable prices

COMPARISON OF PALLET-STORAGE ADVANTAGES AND DISADVANTAGES

-

Different varieties can be stored in a single storage unit

-

Smooth loading and unloading means operativity

-

Easy adaptations of older buildings into pallet storage units

-

Post-harvest drying efficiency is lower compared with bulk storage

-

Produce in pallets is cooled down more slowly – gradually from the outside to the centre of the pallet

-

The need to invest in pallets

See how Agroel ISK units work:

ISK COMPONENTS:

- An inlet control hatcha lets the fresh outdoor (ambient) air enter the storage area. The ambient air can be mixed by the hatch with indoor air in order to achieve the required temperature of the air that enters the storage area (compare to a bathroom water valve). The hatch is operated by an electric linear or radial actuator with a position sensor.

- An outlet hatch allows the warm air to leave the storage area. The hatch is usually placed near the storage ceiling in one of the outside walls, often in the same wall as the inlet hatch. It is also operated by either a radial or a linear actuator.

- A Fan distributes air throughout the storage.

- Outlet pipes plastic pipes distribute air from fans to the area above the top pallets..

- A condensing unit one of the components of a refrigeration system; it in fact transfers heat from the storage area to the outside environment (parts include compressors, a condenser, a pressure vessel and control equipment) .

- An evaporator (cooler) cools recirculated indoor air that passes through it. An evaporator consists of copper pipes for refrigerant distribution and lamellas for heat transfer.

- Air-humidifying panels not only humidify the air that passes through them, but can also provide a significant cooling effect.

- Control system the most important part of a climate control system.

STORAGE SOLUTIONS AND A PROJECT PREPARATION

A professional design of your storage facility and climate control system is fundamental for your future success. Agroel specialists will be glad to offer their advice that will help you find the optimum solution for your requirements. We provide consulting services free of charge to all of our customers.

Contacts

Agroel s.r.o.

tel.: +420 326 398 517

agroel@agroel.cz

Location

Agroel s.r.o.

9. května 299

294 41 Dobrovice

Workshop

Agroel s.r.o.

Úherce 135

294 41 Dobrovice

tel.: +420 326 398 517

fax: 326 398 504

agroel@agroel.cz

INTERNATIONAL REPRESENTATION

GERMANY

Suderburg & Dreyer

Groß Süstedter Weg 8, 29581 Gerdau

tel.: +49 05808 980077

birger@suderburg-dreyer.de

POLAND

Agrad Krawczyk

Stare Płowki 8a, 88-200 Radziejów

tel.: +48 603 127 527

agradkrawczyk@wp.pl

SLOVAKIA

Triton Famme s.r.o.

Levočská 862/28, 058 01 Poprad

tel.: +421 905 829 763

triton@famme.sk

HUNGARY

TRI-ÓZON Kft.

Szalvai Mihály u. 42, 9012 GYOR, HU

tel.: +36 309 569 150

triozon@triozon.hu

UKRAINE

Tesso Engineering s.r.o.

Holečkova 789/49, Smíchov, 150 00 Praha

tel.: +380 963 332 828

tesso.eng@gmail.com

KAZAKHSTAN

CT Agro

Shughyla St 23/1, Astana 010000, Kazachstán

tel.: +7 7172 57 23 53

kuanysh.akshanov@ctagro.de

RUSSIA

OOO STROITELNAYA KOMPANIYA „PROMCHOLOD“

UL. BABEFA 8/2, 414014 ASTRACHAN, RU

tel.: +7 927 282 1972

info@iceprom.ru